Technical specifications

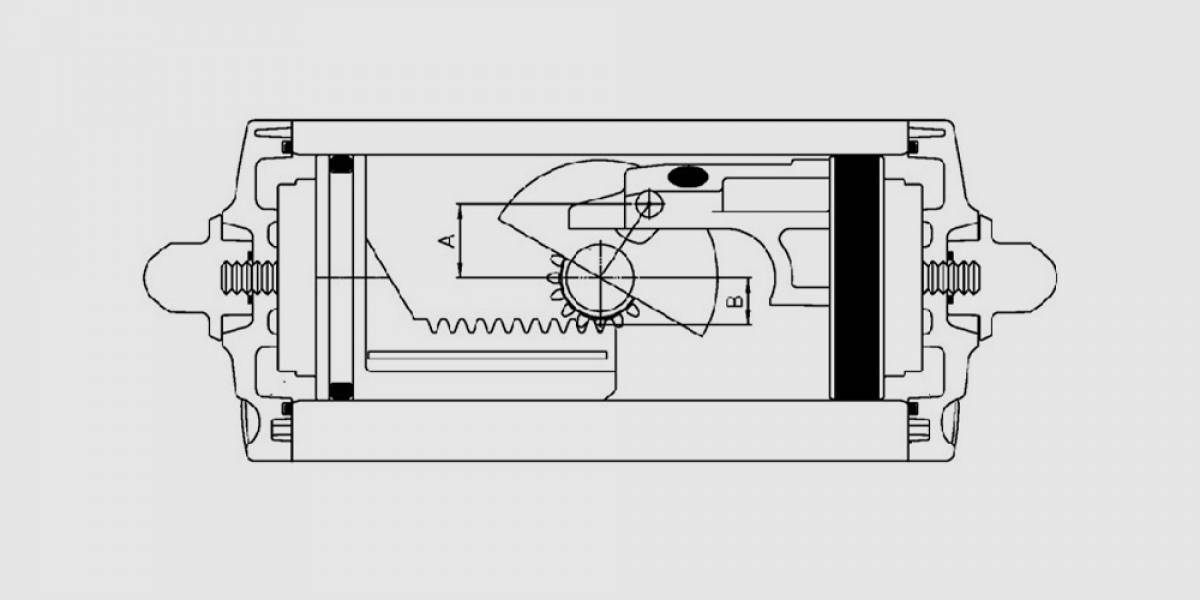

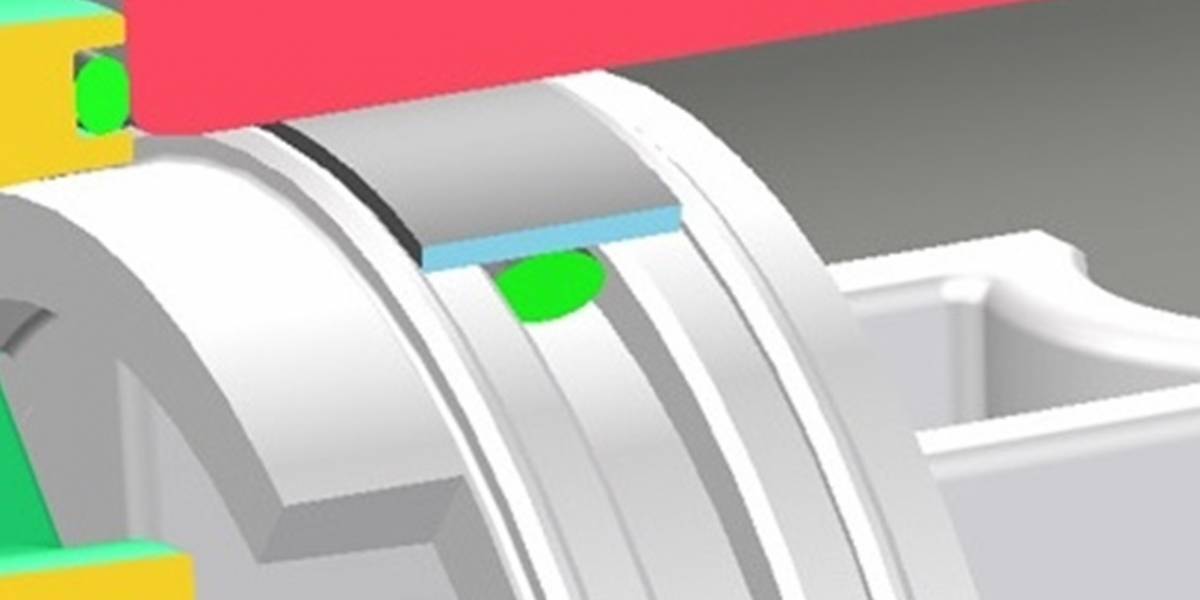

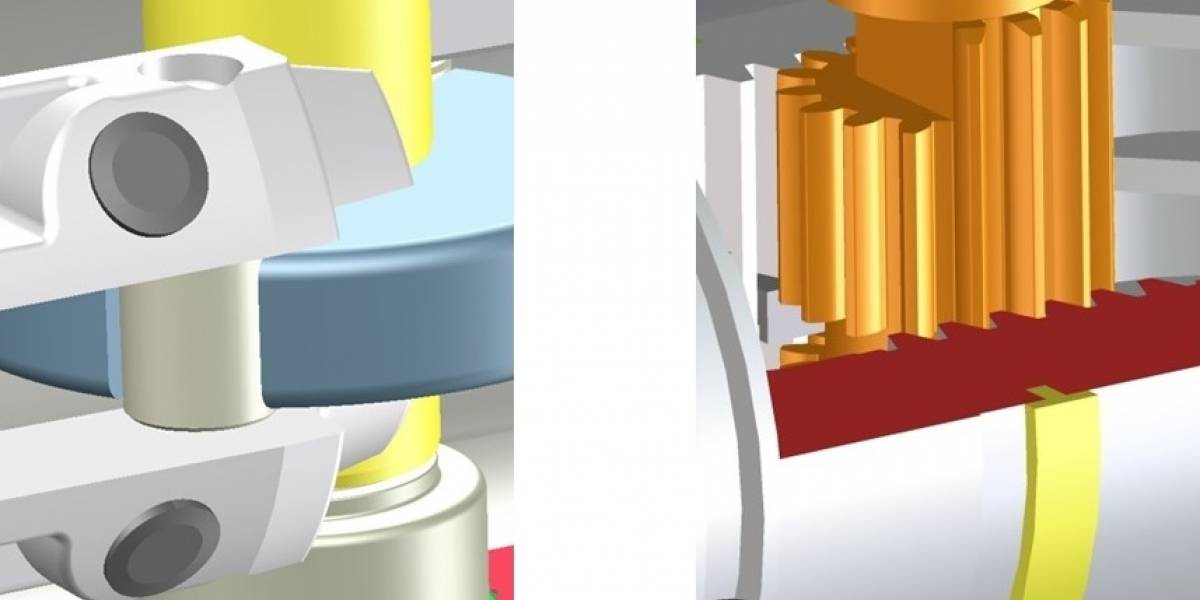

Scotch Yoke mechanism

The distinctive feature of the ACTUATECH product range are the quarter-turn pneumatic Scotch Yoke actuators. Alternative system to the classic Rack & Pinion, which has numerous advantages, including increased torque and lower air consumption, with consequent energy savings.