1.Energized and self-lubricated strips

Less friction between piston and cylinder

It prevents the bonding of the seal to the cylinder even after long periods of inactivity

2.Slots, bushes and pins made by steel with hardness higher than 50 HRC

Higher resistance to the forces inside the actuator

3.Rolling friction between piston and slot

Less friction

4.Scotch yoke with rolling friction (transforming rotary motion into linear motion using piston and shaft without teeths/gears)

Reduced friction between piston and shaft with consequently less wear on the relevant parts

Empowered Breakaway Torque (BTO & BTC)

Smaller volume/size than rack and pinion actuators (with the same torque) therefore less space required for installation

Less weight than the rack and pinion (-30% kg / Nm), with consequent savings on the construction sizing of the plant/equipment

Lower air consumption compared to the rack and pinion actuators (-40% air cm3/Nm for Double Acting and -20% air cm3/Nm for Spring Return) therefore less load on the compressor or the possibility of using a smaller compressor's size.

5.Rolled cylinder

Less wear of the energized ties thanks to the low roughness of the surface

6.Stainless steel shaft

Higher corrosion resistance

From sizes bigger than GD15, NAMUR interface for solenoid valve is already integrated.

No need for extra plate.

100% in- house manufacturing process technology

Maximum control and accuracy in all the stages of the manufacturing process

ATEX Certificate

Installation is allowed in a potential explosive environment

Up to SIL 3 Certified

Guarantee of the high level of functional safety.

TECHNICAL FEATURES

Torque from 30 Nm to 1920 Nm

Mounting flange according to EN ISO 5211

F05 - F07 - F10 - F12 - F14 - F16

In compliance with EN 15714-3

Rotation angle: 92° (-1°, +91°)

Torque: the return torque depends on spring action only notwithstanding the air supply. The spring is provided in four different sizes (see table)

The actuator automatic closing takes place in clockwise direction by means of its springs

In the code of standard version GSV actuators, it is indicated the size of the springs (6=5,6 bar) followed by the breakaway torque in Nm at 5,6 bar air supply.

ATEX version in conformity with directive 2014/34/EU

WORKING CONDITION

Temperature: from -20°C to +80°C (Special versions: high temperature= -20°C +150°C; low temperature= -50°C +60°)

Air supply: 5,6 bar; maximum 8,4 bar

Actuating media: filtered dry compressed air, not necessarily lubricated

In case of lubricated air, either non detergent oil, NBR compatible oil, must be used.

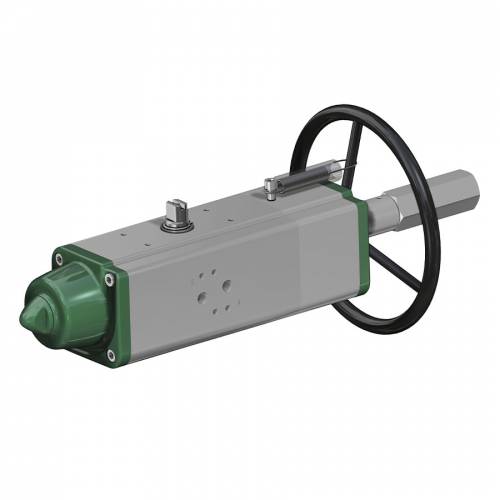

Once required the quarter turn pneumatic actuator can be equipped with a manual handwheel.

The device can be integrated either in Double Acting and Spring Return versions. For the proper functioning of the system and for the mechanical integrity of the device is essential to ensure that the pneumatic actuator is disconnected from the power lines of compressed air before performing any operation using the manual handwheel.

The manual handwheel acts on the transmission of the primary mechanical transmission of the pneumatic actuator and with torques applied to the handwheel according to EN 12570 it releases output torque of equal value of the nominal torque of the actuator.

| DATA SHEET GSV30 ÷ GSV240 | ||||||||

| Code | GSV0030401S | GSV0030402S | GSV0053401S | GSV0060401S | GSV0090401S | GSV0120401S | GSV0180401S | GSV0240401S |

| Spare Seals | KGGI0016VX | KGGI0016VX | KGGI0060VX | KGGI0018VX | KGGI0019VX | KGGI0020VX | KGGI0021VX | KGGI0022VX |

| Size | GSV30 | GSV30 | GSV53 | GSV60 | GSV90 | GSV120 | GSV180 | GSV240 |

| ISO | F04 | F05/F07 | F05/F07 | F05/F07 | F07/F10 | F07/F10 | F07/F10 | F10/F12 |

| A | 392,7 | 392,7 | 431,4 | 457,7 | 534,9 | 558,5 | 635 | 700,8 |

| B | 14 | 14 | 17 | 17 | 22 | 22 | 22 | 27 |

| C x depth | M5x8 | M6x9 | M6x9 | M6x9 | M8x12 | M8x12 | M8x12 | M10x15 |

| D x depth | - | M8x12 | M8x12 | M8x12 | M10x15 | M10x15 | M10x15 | M12x18 |

| E | 42 | 50 | 50 | 50 | 70 | 70 | 70 | 102 |

| F | - | 70 | 70 | 70 | 102 | 102 | 102 | 125 |

| G | 13 | 13 | 13 | 13 | 16 | 17 | 19 | 19 |

| H | 33,7 | 33,7 | 40,8 | 42,8 | 52,5 | 56,1 | 58 | 57,4 |

| J | 18 | 18 | 18 | 18 | 18 | 18 | 18 | 16 |

| K | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 16 |

| I | 10 | 10 | 12 | 12 | 15 | 15 | 19 | 19 |

| L | 90,4 | 90,4 | 103,3 | 107 | 137,5 | 141,1 | 148 | 164,9 |

| M | 37,7 | 37,7 | 44,8 | 46,8 | 56,5 | 60,1 | 62 | 72,9 |

| N | 52,7 | 52,7 | 58,5 | 60,2 | 81 | 81 | 86 | 92 |

| O | 16,5 | 16,5 | 19,3 | 19,3 | 24,8 | 24,8 | 24,3 | 29,5 |

| P | 32,7 | 32,7 | 38,5 | 40,2 | 51 | 51 | 56 | 62 |

| Q | 37,7 | 37,7 | 44,8 | 46,8 | 56,5 | 60,1 | 62 | 72,9 |

| R | 14,5 | 14,5 | 16,2 | 18 | 20,2 | 22,5 | 25,5 | 29 |

| S | 20 | 20 | 20 | 20 | 30 | 30 | 30 | 30 |

| T | 70,4 | 70,4 | 83,3 | 87 | 107,5 | 111,1 | 118 | 134,9 |

| U | 129,4 | 129,4 | 152,1 | 169,3 | 196,8 | 204,8 | 237 | 260,2 |

| V | 180 | 180 | 180 | 180 | 220 | 220 | 300 | 300 |

| W (Gas) | 1/8" | 1/8" | 1/8" | 1/8" | 1/8" | 1/8" | 1/8" | 1/4" |

| X | 4 | 4 | 4 | 4 | 4 | 4 | 4 | - |

| Y | 137,6 | 137,6 | 154,8 | 163,9 | 183,5 | 199,1 | 220,8 | 236,4 |

| Z | 263,3 | 263,3 | 279,3 | 288,4 | 338,1 | 353,7 | 398 | 440,6 |

| Ch | 13 | 13 | 17 | 17 | 22 | 22 | 22 | 27 |

| N°of turns* | 11 | 11 | 13 | 14 | 16 | 18 | 15 | 16 |

| Weight (Kg) | 3,2 | 3,2 | 4,5 | 5,3 | 6,8 | 9 | 11,7 | 15,2 |

| Air (dm³/cycle) | 0,17 | 0,17 | 0,3 | 0,33 | 0,55 | 0,8 | 1 | 1,5 |

| DATA SHEET GSV360 ÷ GSV960 | |||||||

| Code | GSV0360401S | GSV0480401S | GSV0480402S | GSV0720401S | GSV0720402S | GSV0960401S | GSV0960402S |

| Spare Seals | KGGI0023VX | KGGI0024VX | KGGI0024VX | KGGI0025VX | KGGI0025VX | KGGI0026VX | KGGI0026VX |

| Size | GSV360 | GSV480 | GSV480 | GSV720 | GSV720 | GSV960 | GSV960 |

| ISO | F10/F12 | F10/F12 | F14 | F14 | F12 | F14 | F12/F16 |

| A | 810,1 | 842,4 | 842,4 | 1035,4 | 1035,4 | 1067,7 | 1067,7 |

| B | 27 | 36 | 36 | 36 | 36 | 46 | 46 |

| C x depth | M10x15 | M10x15 | M16x24 | M16x24 | M12x18 | M16x24 | M12x18 |

| D x depth | M12x18 | M12x18 | - | - | - | - | M20x30 |

| E | 102 | 102 | 140 | 140 | 125 | 140 | 125 |

| F | 125 | 125 | - | - | - | - | 165 |

| G | 19,5 | 19,5 | 19,5 | 19,5 | 19,5 | 18,5 | 18,5 |

| H | 61,5 | 78 | 78 | 86,5 | 86,5 | 99,2 | 99,2 |

| J | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

| K | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

| I | 22 | 24 | 24 | 27 | 27 | 32 | 32 |

| L | 178 | 198 | 198 | 216 | 216 | 237,7 | 237,7 |

| M | 78,5 | 93,5 | 93,5 | 101,5 | 101,5 | 114,7 | 114,7 |

| N | 99,5 | 104,5 | 104,5 | 114,5 | 114,5 | 123 | 123 |

| O | 29,5 | 38,5 | 38,5 | 38,5 | 38,5 | 48,5 | 48,5 |

| P | 69,5 | 74,5 | 74,5 | 84,5 | 84,5 | 93 | 93 |

| Q | 78,5 | 93,5 | 93,5 | 101,5 | 101,5 | 114,7 | 114,7 |

| R | 31,8 | 36,5 | 36,5 | 41 | 41 | 46 | 46 |

| S | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| T | 148 | 168 | 168 | 186 | 186 | 207,7 | 207,7 |

| U | 306,6 | 324,1 | 324,1 | 399 | 399 | 414 | 414 |

| V | 350 | 350 | 350 | 400 | 400 | 400 | 400 |

| W (Gas) | 1/4" | 1/4" | 1/4" | 1/4" | 1/4" | 1/4" | 1/4" |

| X | - | - | - | - | - | - | - |

| Y | 282,3 | 297,1 | 297,1 | 365,6 | 365,6 | 382,9 | 382,9 |

| Z | 503,5 | 518,3 | 518,3 | 636,4 | 636,4 | 653,7 | 653,7 |

| Ch | 27 | 27 | 27 | 36 | 36 | 36 | 36 |

| N°of turns* | 19 | 20 | 20 | 25 | 25 | 26 | 26 |

| Weight (Kg) | 19,5 | 28,1 | 28,1 | 38,8 | 38,8 | 50,6 | 50,6 |

| Air (dm³/cycle) | 2 | 2,8 | 2,8 | 4,2 | 4,2 | 5,9 | 5,9 |

| DATA SHEET GSV1920 | |

| Code | GSV1920E1608A |

| Spare Seals | KGGI0230VX |

| Size | GSV1920 |

| ISO | F16 |

| N°of turns* | 30 |

| Weight (Kg) | 91 |

| Air (dm³/cycle) | 12,5 |

| MATERIALS UP TO GSV960 | |||

| Pos | Denomination | Q. | Material |

| 1 | Screw | 1 | Stainless Steel |

| 2* | Washer for roller bearings | 4 | Steel alloy |

| 3* | Roller bearings | 2 | Steel alloy |

| 4 | Flange | 1 | Aluminium alloy |

| 5 | Centering ring (Only for GSV360) | 1 | Aluminium alloy |

| 6* | O'ring (Only for GSV360) | 1 | Nitrilic rubber |

| 7* | O'ring | 2 | Nitrilic rubber |

| 8* | O'ring | 1 | Nitrilic rubber |

| 9* | O'ring | 1 | Nitrilic rubber |

| 10* | O'ring | 1 | Nitrilic rubber |

| 11 | Screw | 1 | Stainless Steel |

| 12 | Spring | 1 | Stainless Steel |

| 13 | Cylinder spacer | 1 | Aluminium alloy |

| 14* | O'ring | 1 | Nitrilic rubber |

| 15* | Seal cap | 1 | Brass+Nitrilic rubber |

| 16 | Cap (modified) | 1 | Aluminium alloy |

| 17 | Screw | 4 | Stainless Steel |

| 18* | O'ring | 1 | Nitrilic rubber |

| 19 | Handwheel for maneuever | 1 | Steel alloy |

| 20 | Set screw | 2 | Stainless Steel |

| 21 | Protecting tube | 1 | Aluminium alloy |

| 22 | Trasparent tube | 1 | PVC |

| 23 | Protecting cap | 1 | Aluminium alloy |

| 24 | Key | 1 | Steel alloy |

| 25 | Spring | 2 | Steel alloy |

| 26* | Rivet | 1 | Steel alloy |

| 27* | Indicator | 1 | Polypropylene |

| 28 | Lead nut maneuever | 1 | Steel alloy |

| 29 | Threaded bush (Only for GSV240) | 2 | Stainless Steel |

| 30 | Special spring cap | 1 | Aluminium alloy |

| 31 | Pin | 1 | Steel alloy |

| 32 | Screw maneuever | 1 | Steel alloy |

| 33* | Dynamic seal (Piston) | 2 | Polyurethane |

| 34* | Piston o'ring | 2 | Nitrilic rubber |

| 35 | Piston (modified) | 1 | Aluminium alloy |

| 36* | Piston's support | 4 | P.T.F.E. carbo-graphite filled |

| 37 | Bush | 2 | Steel alloy |

| 38 | Rotative sleeve | 2 | Steel alloy |

| 39* | Bounded | 2 | Steel alloy+Nitrilic rubber |

| 40 | Screw | 2 | Stainless Steel |

| 41 | Scotch yoke | 1 | Steel alloy |

| 42 | Shaft support | 1 | Acetalic resin |

| 43 | External elastic pin of the yoke | 1 | Steel alloy |

| 44 | Internal elastic pin of the yoke | 1 | Steel alloy |

| 45 | Shaft | 1 | Stainless Steel |

| 46 | Support bush | 1 | Acetalic resin |

| 47 | Lower sealing shaft | 1 | FKM |

| 48 | Cylinder | 1 | Aluminium alloy |

| 49 | Upper sealing shaft | 1 | FKM |

| 50 | External support ring | 1 | Acetalic resin |

| 51 | Washer | 1 | Stainless Steel |

| 52 | Seeger | 1 | Stainless Steel |

| 53 | Piston (Standard) | 1 | Aluminium alloy |

| 54 | Spring loading screw | 1 | Stainless Steel |

| 55 | Spring cap (Standard) | 1 | Steel alloy or Aluminium alloy |

| 56* | Cap o'ring | 1 | Nitrilic rubber |

| 57 | Cap (Standard) | 1 | Aluminium alloy |

| 58 | Screw | 4 | Stainless Steel |

| 59* | O'ring | 1 | Nitrilic rubber |

| 60 | Nut | 1 | Aluminium alloy |

| 61 | Insert for o'ring (Only for GSV53-120-180-360) | 1 | Stainless Steel |

| * Components of spare part kit | |||

| MATERIALS GSV1920 | |||

| Pos | Denomination | Q.ty | Material |

| 1 | Cylinder | 1 | Aluminium alloy |

| 2 | Cylinder | 1 | Aluminium alloy |

| 3 | Cylinder | 1 | Aluminium alloy |

| 4 | Cap (Standard) | 1 | Aluminium alloy |

| 5 | Internal spring support | 1 | Aluminium alloy |

| 6 | External spring support | 1 | Aluminium alloy |

| 7 | Spring loading screw | 1 | Stainless Steel |

| 8* | O'ring | 1 | Nitrilic rubber |

| 9 | Cap Nut | 1 | Stainless Steel |

| 10 | O'ring | 1 | Nitrilic rubber |

| 11 | O'ring | 1 | Nitrilic rubber |

| 12 | Nut | 1 | Stainless Steel |

| 13 | External spring | 2 | Steel alloy |

| 14 | Internal spring | 2 | Steel alloy |

| 15 | Piston (Standard) | 1 | Aluminium alloy |

| 16 | Bush | 2 | Steel alloy |

| 17* | Piston's support | 4 | Acetalic resin |

| 18 | Pin | 2 | Steel alloy |

| 19 | Rotative sleeve | 2 | Steel alloy |

| 20 | Scotch yoke | 1 | Steel alloy |

| 21 | Shaft | 1 | Stainless Steel |

| 22 | Support bush | 1 | Acetalic resin |

| 23 | Shaft support | 1 | Acetalic resin |

| 24* | Cap o'ring | 1 | Nitrilic rubber |

| 25* | Bearing (shaft bottom) | 1 | P.T.F.E. carbo-graphite filled |

| 26* | Bearing (shaft top) | 1 | P.T.F.E. carbo-graphite filled |

| 27* | External support ring | 1 | Acetalic resin |

| 28 | Washer | 1 | Stainless Steel |

| 29* | O'ring | 3 | Nitrilic rubber |

| 30 | Seeger | 1 | Stainless Steel |

| 31 | Screw | 6 | Stainless Steel |

| 32* | Lower sealing shaft | 1 | FKM |

| 33* | Piston o'ring | 2 | Nitrilic rubber |

| 34* | Upper sealing shaft | 1 | FKM |

| 35* | O'ring | 2 | Nitrilic rubber |

| 36* | Bearing (piston head) | 2 | P.T.F.E. Carbo-Graphite filled |

| 37 | Nut | 12 | Stainless Steel |

| 38 | Piston (modified) | 1 | Aluminium alloy |

| 39* | Bearings (Handwheel) | 2 | Poliuretano |

| 40 | Cap (modified) | 1 | Aluminium alloy |

| 41 | Lead nut maneuever | 1 | Steel alloy |

| 42* | Indicator | 1 | Polypropylene |

| 43 | Handwheel for maneuever | 1 | Steel alloy |

| 44 | Flange | 1 | Aluminium alloy |

| 45* | Thrust bearings | 2 | Steel alloy |

| 46 | Screw | 8 | Stainless Steel |

| 47 | Screw | 1 | Stainless Steel |

| 48 | Washer | 1 | Stainless Steel |

| 49 | Closing fork | 1 | Aluminium alloy |

| 50 | Fork support | 1 | Aluminium alloy |

| 51 | Lock wheel | 1 | Stainless Steel |

| 52 | Protecting cap | 1 | Aluminium alloy |

| 53 | Screw | 3 | Stainless Steel |

| 54* | Rivet | 1 | Stainless Steel |

| 55 | Key | 1 | Stainless Steel |

| 56 | Screw | 6 | Steel alloy |

| 57* | O'ring | 1 | Nitrilic rubber |

| 58* | O'ring | 1 | Nitrilic rubber |

| 59* | O'ring | 1 | Nitrilic rubber |

| 60 | Screw | 2 | Stainless Steel |

| 61* | Bounded | 2 | Steel alloy+Nitrilic rubber |

| 62* | O'ring | 1 | Nitrilic rubber |

| 63* | O'ring | 1 | Nitrilic rubber |

| 64* | Plug | 2 | P.T.F.E |

| 65 | Nut | 1 | Stainless Steel |

| 66 | Screw maneuever | 1 | Stainless Steel |

| 67 | Protecting removable tube | 1 | Aluminium alloy |

| 68 | Pin | 1 | Stainless Steel |

| 69 | Special spring cap | 1 | Steel alloy |

| 70* | O'ring | 1 | Nitrilic rubber |

| 71* | O'ring | 1 | Nitrilic rubber |

| 72 | Screw | 1 | Stainless Steel |

| 73 | Safety screw | 1 | Stainless Steel |

| 74 | Protecting tube | 1 | Aluminium alloy |

| * Components of spare part kit | |||

Drawings on the left = valve in open position

Drawings on the right = valve in closed position

Typical air connection diagram

The pistons of the standard GS actuators are mounted as shown above. Although the spring force is small, the geometry of the mechanism provides more torque at the end of stroke. When the actuator is in the valve open position and the springs are fully compressed, the end stops can be adjusted with precision. Reverse acting spring return actuators are required when the valve needs to open automatically in the case that the pressurized air or power supply is turned off. In reverse acting actuators, the pistons are inserted into the cylinder in the same way as in the Double Acting version and, due to the force of the spring, the actuator opens normally. Caution. The normal torque performance in the reverse acting version, due to its construction, is different from that of the standard version. Caution. To prevent dust or dirt from being sucked into the actuator chamber during spring action, install a filter on port 2. Port 4 is connected to the middle chamber and, when pressurized, the drive shaft rotates anticlockwise to open. In accordance with the international standard ISO 5599-2, the position, location, orientation and shape of the actuator air port connections must be clearly identified and marketed using numbers 2 and 4.

For more information check the ACTUATECH Accessories Catalogue.